Corrugated packaging is one of the most widely used materials in product shipping and retail packaging. It offers a powerful combination of durability, flexibility, and cost-efficiency. From small retail boxes to heavy-duty industrial cartons, custom corrugated packaging plays a vital role in keeping products safe while supporting branding and sustainability goals.

In modern packaging design, brands are not just looking for protective materials—they are also seeking customizable, recyclable, and structurally sound options. Custom corrugated packaging, tailored to meet unique product needs, becomes a smart solution for businesses of all types and sizes.

What Makes Corrugated Packaging So Unique?

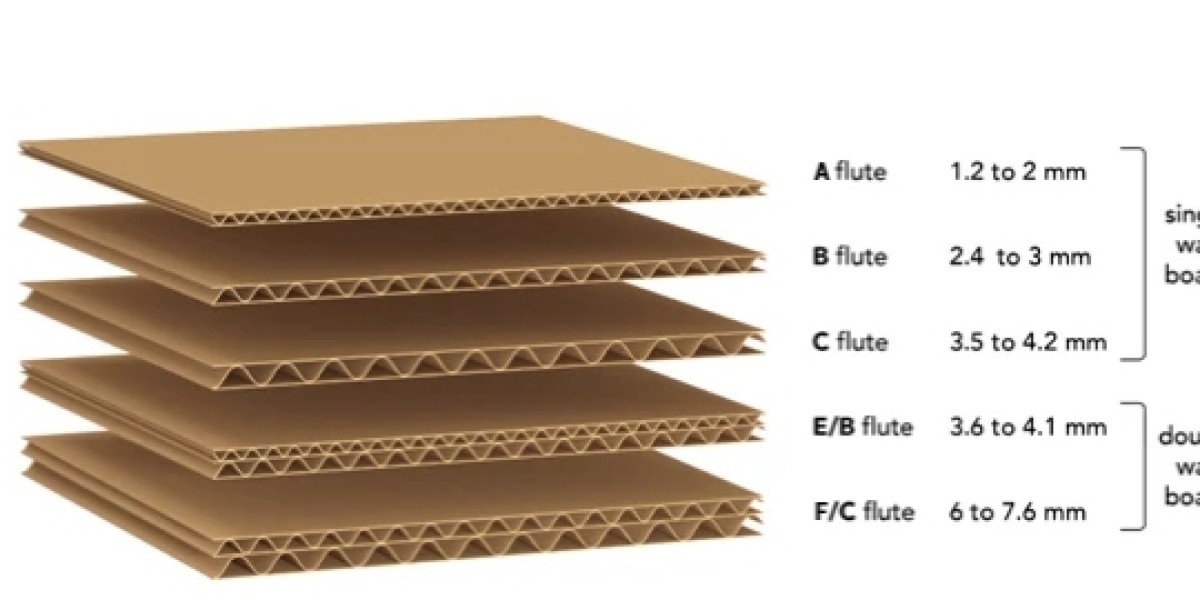

At the core of corrugated packaging lies a functional yet clever structure—corrugated board layers. These layers include a fluted inner layer sandwiched between two flat liners. The fluting provides cushioning and rigidity, helping the box withstand pressure, impact, and moisture. The layers work together to protect the contents during shipping and storage.

There are several types of fluting, each designed with specific characteristics. For instance, A-flute provides excellent cushioning due to its thickness, while B-flute is more compact and provides better crush resistance. C-flute is a popular medium option, balancing strength and printability. Other types like E and F-flutes are thinner and often used for retail or display packaging where aesthetics matter more.

The Importance of Flute Thickness and Wall Types

The strength and performance of corrugated packaging are heavily influenced by flute thickness comparison and wall configuration. Thicker flutes offer more cushioning, while thinner flutes provide better surface for printing and die-cutting.

You’ll often encounter two main wall types:

Single wall: Consists of one fluted medium and two linerboards. This is commonly used for lightweight shipping and retail packaging.

Double wall: Includes two layers of fluting and three linerboards. This option is more suitable for heavy items or fragile products needing extra protection.

Understanding the single wall vs double wall distinction helps in choosing the right construction for your product, ensuring adequate protection without over-packaging or driving up costs.

Why Customization Matters in Corrugated Packaging

In a competitive retail environment, packaging is more than just a container—it’s a marketing tool. Customization allows businesses to tailor every element of the box, including size, shape, material strength, and branding design. This is where custom corrugated packaging becomes invaluable.

A well-designed custom box can:

Fit the product snugly, minimizing material waste

Enhance unboxing experience

Support brand storytelling through printed visuals

Reduce damages during transit

Comply with industry or shipping regulations

Whether you're selling electronics, cosmetics, or food items, having packaging that aligns with your product and brand identity is essential.

Sustainable Options and Eco-Conscious Choices

Today’s consumers are increasingly aware of the environmental impact of packaging. Corrugated materials are often made from recycled paper and are fully recyclable themselves. Many companies now seek eco-friendly options by choosing the right fluting types and box designs that minimize material usage without compromising protection.

Choosing the appropriate flute profile and reducing unnecessary void space not only enhances product security but also contributes to lowering carbon footprints during shipping. Businesses that embrace sustainability through smarter packaging choices can build stronger relationships with eco-conscious customers.

Key Considerations When Choosing Corrugated Packaging

If you're in the process of selecting or developing corrugated packaging for your products, consider these key aspects:

Product Weight & Fragility: Heavier and more delicate items may need double wall or thicker flutes.

Shipping Method: Long-distance or multi-handling requires stronger materials.

Printing Requirements: Retail packaging may need smoother surfaces for better printing results.

Storage Conditions: Moisture resistance and insulation may be necessary depending on where and how your products are stored.

Customization Needs: Incorporate specific dimensions, inserts, or branded designs as required.

By evaluating these factors, you can ensure that your custom corrugated packaging meets both practical and marketing objectives.

Role of Custom Design in Packaging Effectiveness

Design is a critical component in creating boxes that stand out while remaining functional. Working with experienced packaging engineers and designers allows you to combine performance with visual appeal. Advanced die-cutting, folding styles, and innovative inserts all contribute to the end-user experience.

In the age of eCommerce, where unboxing videos and product reviews can influence buying behavior, your packaging becomes a silent ambassador of your brand. Using the right materials and design elements will not only protect your product but also leave a lasting impression.

That's where custom design boxes play a strategic role. From retail displays to shipping cartons, custom designs allow you to differentiate your product in a crowded market. Moreover, leveraging structural design alongside branding elements helps create a package that serves both protection and promotion.

Conclusion

Corrugated packaging remains a cornerstone in both shipping logistics and retail product presentation. When tailored to your business's needs, custom corrugated packaging ensures product safety, enhances customer experience, and reflects your brand’s values. By understanding fluting types, material strength, and custom design possibilities, businesses can make informed decisions that balance durability, cost-effectiveness, and sustainability.

Investing in custom design boxes is more than a packaging upgrade—it's a strategic move to build trust, improve customer satisfaction, and stand out in today’s competitive marketplace.