Graphite Density material science aur industrial engineering ka ek fundamental concept hai jo graphite ke performance, durability aur usability ko directly affect karta hai. Jo users Google par “Graphite Density” search karte hain, unka main objective hota hai graphite ki physical properties ko samajhna, different graphite grades ka comparison karna, aur yeh evaluate karna ke kaunsi density unki application ke liye best rahegi.

Is detailed guide mein hum graphite density ko beginner-friendly language mein explain karenge, saath hi industrial aur technical insights bhi provide karenge — taake yeh article students, engineers, manufacturers aur buyers sab ke liye equally valuable ho.

What Is Graphite Density

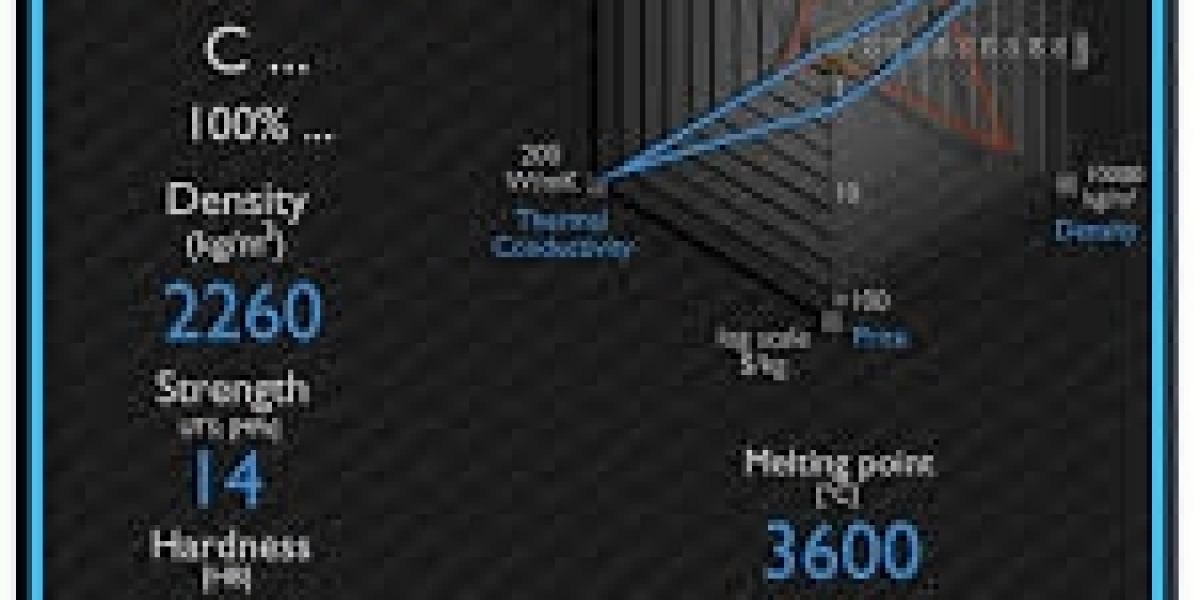

Graphite density ka matlab hota hai graphite ka mass per unit volume. Simple alfaaz mein, yeh batata hai ke graphite kitna compact, solid ya porous hai. Density usually grams per cubic centimeter (g/cm³) ya kilograms per cubic meter (kg/m³) mein measure ki jati hai.

Graphite carbon ka crystalline form hota hai, lekin iska atomic arrangement layered hota hai. Isi layered structure ki wajah se graphite ki density diamond jaise carbon forms se kam hoti hai.

Why Graphite Density Is Important

Graphite density sirf ek number nahi hota, balkay yeh graphite ke mechanical strength, electrical conductivity, thermal behavior aur lifespan ko determine karta hai.

Zyada density → zyada strength aur durability

Kam density → lightweight aur insulation properties

Balanced density → cost-effective industrial performance

Isi liye graphite selection mein density ek decisive factor hoti hai.

Typical Density Range of Graphite

Graphite ki density ek fixed value nahi hoti, balkay type aur manufacturing process ke sath change hoti rehti hai:

Natural graphite density: approx. 2.1 – 2.3 g/cm³

Synthetic graphite density: approx. 1.6 – 2.2 g/cm³

High-density graphite: 1.9 g/cm³ ya us se zyada

Low-density graphite: 1.5 – 1.8 g/cm³

Higher density graphite zyada compact hota hai, jab ke lower density graphite mein porosity zyada hoti hai.

Factors That Affect Graphite Density

Raw Material Quality

High-purity carbon sources graphite ki density ko improve karte hain. Impurities porosity increase karti hain, jis se density kam ho jati hai.

Manufacturing Process

Extrusion, molding aur isostatic pressing jaise processes graphite density par direct impact dalte hain.

Porosity Level

Graphite jitna zyada porous hoga, uski density utni hi kam hogi.

Heat Treatment

High-temperature graphitization carbon atoms ko tightly bond karta hai, jis se density increase hoti hai.

Types of Graphite Based on Density

Low Density Graphite

Low density graphite lightweight hota hai aur thermal insulation applications ke liye suitable hota hai. Yeh wahan use hota hai jahan heat resistance zyada aur mechanical load kam hota hai.

Medium Density Graphite

Medium density graphite balanced performance provide karta hai. Yeh industrial machinery, seals aur general-purpose components mein commonly use hota hai.

High Density Graphite

High density graphite maximum strength, wear resistance aur conductivity offer karta hai. Yeh high-performance aur high-temperature environments ke liye ideal hota hai.

Role of Graphite Density in Industrial Applications

Battery Industry

Lithium-ion batteries mein graphite anodes ki density battery capacity aur charging efficiency ko directly impact karti hai.

Metallurgical Applications

Furnace linings, crucibles aur molds ke liye high density graphite preferred hota hai kyunki yeh extreme heat ko handle kar sakta hai.

Electrical & Electronic Uses

Electrodes aur current-carrying components mein graphite density electrical conductivity ko optimize karti hai.

Mechanical Seals & Bearings

High density graphite wear resistance aur self-lubricating properties offer karta hai.

Aerospace & Nuclear Sector

Controlled graphite density extreme environments mein reliability aur safety ensure karti hai.

Graphite Density vs Other Carbon Materials

Graphite ko jab charcoal, coke aur carbon fiber se compare kiya jata hai, to graphite ki density zyada uniform aur predictable hoti hai. Isi uniformity ki wajah se graphite industrial design aur engineering applications ke liye preferred material banta hai.

How to Choose the Right Graphite Density

Graphite density select karte waqt yeh points consider karna zaroori hota hai:

Application ka temperature range

Mechanical load requirements

Electrical aur thermal conductivity needs

Cost aur lifecycle expectations

Sahi density choose karna long-term performance aur maintenance cost dono ko reduce karta hai.

FAQs About Graphite Density

Graphite density ka average value kya hota hai

Graphite ki density generally 1.6 se 2.3 g/cm³ ke beech hoti hai.

High density graphite kahan use hota hai

High density graphite batteries, electrodes, furnaces aur aerospace components mein use hota hai.

Low density graphite ka kya advantage hai

Low density graphite lightweight hota hai aur thermal insulation ke liye ideal hota hai.

Kya graphite density performance ko affect karti hai

Yes, density graphite ki strength, conductivity aur durability ko directly affect karti hai.

Kya graphite density customize ki ja sakti hai

Haan, manufacturing aur heat treatment processes ke zariye graphite density ko control kiya ja sakta hai.

Conclusion:

FAQs ke baad yeh bilkul clear ho jata hai ke Graphite Density sirf ek technical specification nahi balkay graphite ke overall performance ka backbone hai. Chahe baat ho batteries ki, metallurgical processes ki ya advanced engineering applications ki — graphite density har jagah critical role play karti hai.

High density graphite strength, reliability aur long service life provide karta hai, jab ke low density graphite lightweight aur insulation-focused solutions ke liye perfect hota hai. Isi liye correct graphite density ka selection efficiency, safety aur cost optimization ke liye bohot zaroori hai.

Aaj ke fast-evolving industrial landscape mein graphite density ko samajhna aur sahi tarah apply karna businesses aur engineers dono ke liye competitive advantage ban chuka hai. Agar aap quality, performance aur durability chahte hain, to graphite density ko ignore karna kabhi bhi sahi choice nahi hogi.