The electromagnetic flowmeter market size has been growing steadily due to technological innovations and increasing application areas. As industries strive for better process control, the demand for accurate, non-invasive, and low-maintenance flow measurement devices is driving market expansion. Market size projections indicate strong growth in both developed and emerging economies, with manufacturers investing in scalable solutions to cater to various industrial applications. The market size is also influenced by strategic partnerships and collaborations, enabling companies to penetrate untapped sectors and enhance their regional presence.

The electromagnetic flowmeter market has witnessed steady growth over the past few years, driven by the increasing need for precise and reliable flow measurement in various industries. Electromagnetic flowmeters, also known as magmeters, operate on Faraday's law of electromagnetic induction to measure the flow rate of conductive liquids. Their non-intrusive design, low maintenance requirements, and high accuracy make them ideal for applications in water and wastewater treatment, chemical processing, food and beverage, and pharmaceuticals. As industries continue to focus on automation, process optimization, and energy efficiency, the demand for advanced flow measurement solutions like electromagnetic flowmeters is expected to rise further.

Market Dynamics

Drivers of Market Growth

Several factors are fueling the expansion of the electromagnetic flowmeter market. The increasing emphasis on water conservation and wastewater management has prompted municipalities and industrial facilities to adopt advanced flow measurement technologies. Electromagnetic flowmeters offer precise measurement even in challenging conditions, such as dirty or corrosive liquids, which makes them highly suitable for water treatment plants. Additionally, industries are increasingly focusing on process automation and monitoring, and the integration of electromagnetic flowmeters with digital control systems enhances real-time data collection and operational efficiency.

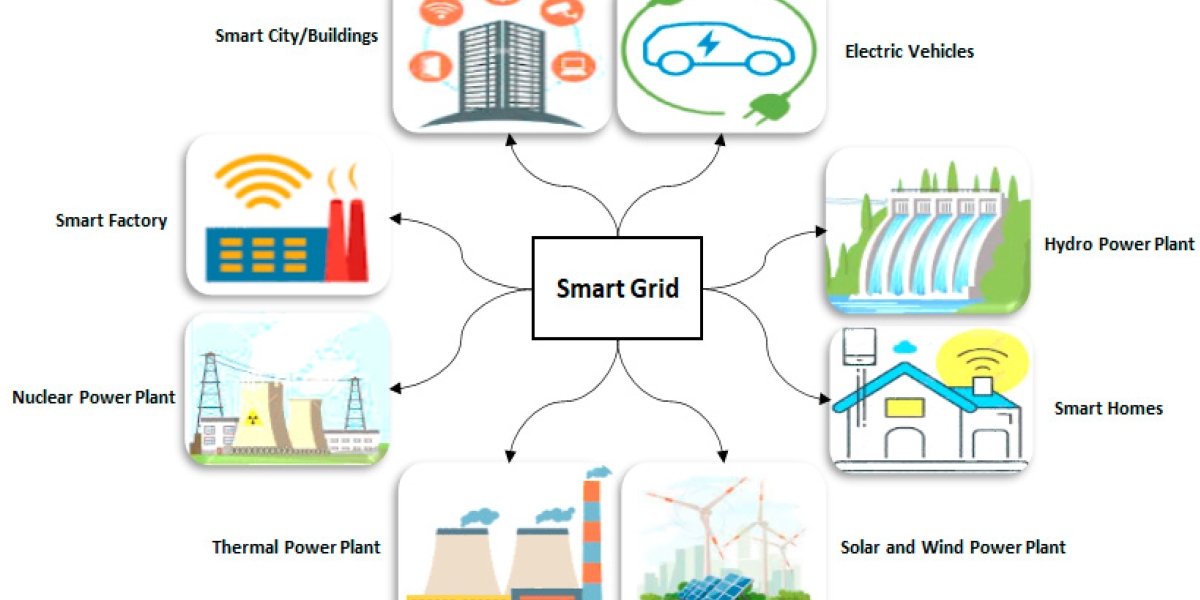

The growing adoption of smart technologies and Industry 4.0 practices also contributes to market growth. With the rise of IoT-enabled devices, electromagnetic flowmeters can now offer remote monitoring, predictive maintenance, and seamless integration with SCADA systems. This not only improves operational efficiency but also reduces the likelihood of downtime, which is a critical consideration for industries relying on continuous production processes.

Market Restraints

Despite their advantages, electromagnetic flowmeters face certain limitations that can restrain market growth. The initial cost of installation and calibration can be relatively high compared to traditional flow measurement devices, which may deter small and medium-sized enterprises. Additionally, electromagnetic flowmeters require the fluid to be conductive, limiting their use for non-conductive liquids such as oils or distilled water. Maintenance and skilled workforce requirements can also pose challenges in regions where technical expertise is scarce.

Market Segmentation

The electromagnetic flowmeter market is segmented based on type, application, end-user industry, and region.

By Type

Electromagnetic flowmeters are broadly categorized into in-line flowmeters and insertion flowmeters. In-line flowmeters are preferred for pipelines with consistent flow, offering high accuracy and low maintenance. Insertion flowmeters, on the other hand, are easier to install and ideal for large-diameter pipes where in-line installation may be challenging. Each type caters to specific industrial requirements, and the selection depends on factors such as pipe size, fluid type, and measurement accuracy needed.

By Application

Applications of electromagnetic flowmeters span across water treatment, chemical processing, pulp and paper, food and beverage, and pharmaceutical industries. Water and wastewater treatment remain the largest application segment due to stringent regulations and the need for efficient resource management. Chemical and pharmaceutical industries require accurate flow measurement to ensure precise mixing and formulation, while the food and beverage sector emphasizes hygiene and contamination-free flow measurement, making electromagnetic flowmeters an ideal choice.

By End-User Industry

Key end-user industries include municipal water utilities, oil and gas, chemicals, food and beverages, pharmaceuticals, and power generation. Municipal water utilities dominate market demand, driven by infrastructure development and modernization of water supply and treatment systems. In oil and gas, flowmeters are essential for monitoring slurry, wastewater, and other conductive fluids. The chemical and pharmaceutical sectors rely on these devices for process control and quality assurance.

Regional Insights

The electromagnetic flowmeter market is geographically diverse, with significant demand across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. North America and Europe have mature markets due to well-established industrial infrastructure and strict environmental regulations. Asia-Pacific, however, is expected to witness the highest growth rate, fueled by rapid industrialization, urbanization, and large-scale water infrastructure projects in countries like China and India. Emerging economies in Latin America and the Middle East are also contributing to market expansion as they invest in advanced water treatment facilities and industrial automation.

Technological Advancements

Recent advancements in electromagnetic flowmeter technology are enhancing market potential. Modern magmeters feature digital displays, remote monitoring capabilities, and improved signal processing, which increases accuracy and reliability. The integration of IoT and cloud-based analytics allows industries to track flow patterns, predict maintenance needs, and optimize operations in real-time. Additionally, the development of compact and energy-efficient designs has expanded the use of electromagnetic flowmeters in small-scale and decentralized systems.

Challenges and Future Outlook

While the market shows promising growth, it faces challenges such as high upfront costs, technical expertise requirements, and competition from alternative flow measurement technologies like ultrasonic and Coriolis flowmeters. However, ongoing research and innovation are expected to overcome these barriers. Companies are focusing on cost-effective solutions, easy installation options, and enhanced compatibility with industrial automation systems.

Looking forward, the electromagnetic flowmeter market is poised for sustained growth driven by rising infrastructure investments, increasing industrial automation, and stringent regulations for water and environmental management. As industries continue to adopt smart technologies, the demand for highly accurate, reliable, and low-maintenance flow measurement solutions will further drive market expansion.

Conclusion

The electromagnetic flowmeter market is evolving rapidly, supported by industrial growth, technological advancements, and increasing demand for precise flow measurement. With applications spanning water treatment, chemicals, pharmaceuticals, and food processing, these devices are integral to efficient and sustainable industrial operations. Despite certain challenges, innovations in IoT integration, digital monitoring, and energy-efficient designs are expected to enhance adoption across industries. The market outlook remains positive, with opportunities for both established players and new entrants to capitalize on the growing emphasis on process optimization, regulatory compliance, and smart industrial solutions.