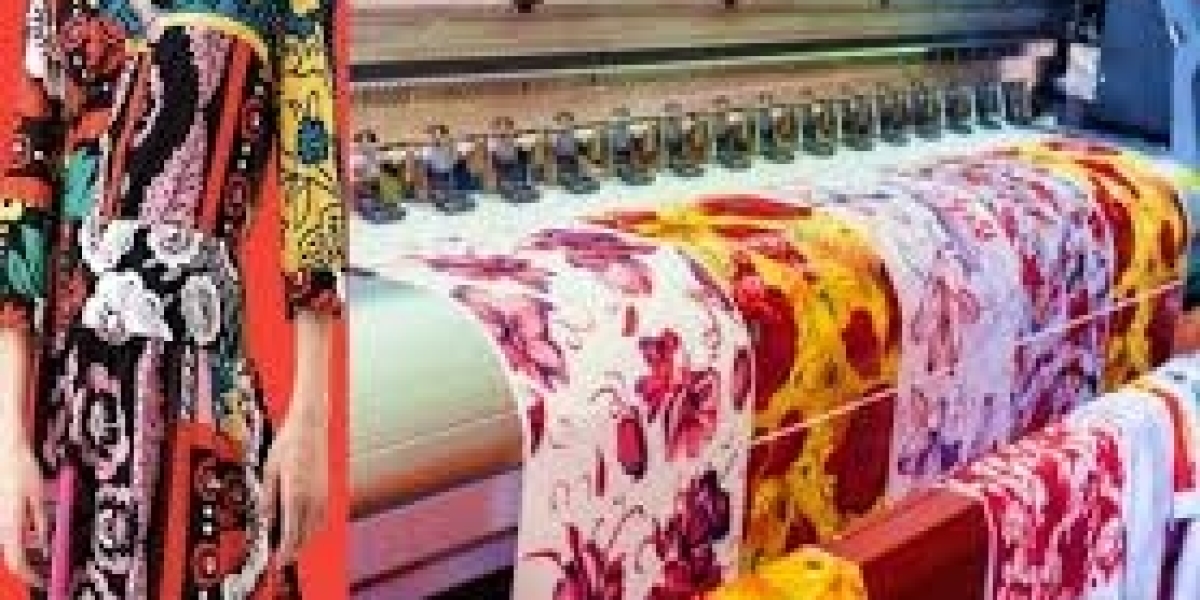

In today’s fast-paced and design-driven world, the textile industry is undergoing a creative revolution. The rise of custom digital printing on fabric has transformed how patterns, colors, and textures are brought to life — offering a perfect blend of technology, artistry, and precision.

This innovative method gives designers, brands, and artists complete creative freedom. From intricate illustrations and photographic prints to bold modern designs, every idea can be printed directly onto fabric with flawless detail and vibrant color depth. Unlike traditional printing techniques, which require heavy setup and limited color ranges, digital printing offers speed, versatility, and sustainable production.

Let’s take an in-depth look at how custom digital fabric printing works, its advantages, applications, and why it has become the heart of modern textile design.

What Is Custom Digital Printing on Fabric?

Custom digital printing on fabric is an advanced printing technology that applies digital artwork directly onto textiles using high-performance inkjet printers. This process doesn’t require screens or rollers — instead, it uses precise digital files to reproduce designs on fabrics like cotton, silk, polyester, linen, and blends.

The result? Unmatched detail, smoother gradients, and eye-catching colors that remain durable over time. It’s ideal for both large-scale manufacturing and small custom orders, giving every piece of fabric a unique and personal identity.

How Digital Fabric Printing Works

The digital printing process is a fine balance between creativity and technology, ensuring that every print maintains artistic integrity and material quality.

Step 1: Design Creation

The process begins with a digital design — created using specialized software such as Adobe Photoshop or Illustrator. This artwork can include patterns, photos, graphics, or any creative concept.

Step 2: Fabric Pre-Treatment

Before printing, fabrics are pre-treated with a coating that enhances ink absorption and ensures vibrant, long-lasting colors.

Step 3: Printing the Design

The digital printer sprays eco-friendly inks onto the fabric with microscopic precision. Depending on the fabric type, different inks (pigment, reactive, or sublimation) are used for optimal results.

Step 4: Fixation and Finishing

Once the design is printed, the fabric goes through a heat or steam fixation process to permanently set the ink. The final washing and finishing give the fabric a soft, smooth texture with excellent durability.

This process delivers quick, high-quality results — making digital printing one of the most efficient and sustainable fabric printing solutions available today.

Key Benefits of Custom Digital Printing on Fabric

Infinite Design Possibilities

Digital printing opens up a world of creative opportunities. Designers can produce everything from delicate watercolor effects to bold, complex imagery without being limited by traditional printing screens or color restrictions.

Exceptional Print Precision

With digital printing, even the smallest details are captured with photographic clarity. The colors are rich, the lines are crisp, and every design is reproduced exactly as envisioned.

Cost-Effective for All Scales

Unlike screen printing, which requires setup costs and bulk production, digital printing is affordable for both short runs and large orders. This makes it ideal for designers who want to test new ideas or produce exclusive, limited-edition collections.

Fast Turnaround and On-Demand Production

Digital printing significantly shortens production time. Designers can move from concept to finished product within days — a major advantage in today’s trend-sensitive market.

Environmentally Conscious

One of the strongest reasons for its popularity is sustainability. Digital printing uses less water, fewer chemicals, and minimal energy, making it a greener alternative to conventional printing. The use of water-based, non-toxic inks further supports eco-friendly production.

Types of Digital Fabric Printing Techniques

Direct-to-Fabric (DTF) Printing

DTF printing involves printing directly onto the fabric using pigment or reactive inks. It provides deep color saturation and a soft finish, making it ideal for natural fabrics like cotton and silk.

Dye-Sublimation Printing

Best suited for polyester materials, dye-sublimation uses heat to transfer the design from paper to fabric. This method produces vivid, fade-resistant prints with a smooth texture.

Reactive Ink Printing

Reactive inks chemically bond with fabric fibers, delivering rich, vibrant colors that stay bright even after multiple washes. It’s commonly used for premium fashion textiles.

Pigment Ink Printing

Pigment inks sit on top of the fabric, creating a sharp, detailed print suitable for upholstery, décor, and fashion accessories. This method requires less water and energy, adding to its eco-friendly appeal.

Applications of Custom Digital Printing on Fabric

Fashion and Apparel

Digital printing has transformed fashion design by allowing unlimited creativity and customization. Designers can print exclusive patterns, create personalized garments, and launch new collections quickly without the high setup costs of traditional printing.

Home Furnishings and Décor

From curtains and cushions to bed linens and wall hangings, custom digital printing brings life and character to home interiors. Designers and homeowners alike can match fabrics to any aesthetic or color theme with perfect precision.

Branding and Corporate Identity

Businesses use digitally printed fabrics for uniforms, promotional displays, banners, and merchandise. The ability to reproduce logos and brand colors with exact accuracy ensures a professional and cohesive look.

Artistic and Creative Projects

Artists, photographers, and illustrators can print their digital artwork directly on textiles, turning creative visions into fabric masterpieces. It’s a perfect fusion of art and innovation.

Why Custom Digital Printing Is the Future of Textile Manufacturing

The future of textile printing lies in personalization, sustainability, and efficiency — and custom digital printing delivers all three.

As consumers demand individuality and eco-friendly products, digital printing offers the perfect solution. It allows brands to produce fabrics on demand, reducing overproduction and waste. The technology’s ability to replicate even the most complex designs makes it ideal for modern designers who value both creativity and responsibility.

Moreover, as printing technologies continue to advance, we can expect even faster production times, greater fabric compatibility, and improved color management — shaping a smarter, more sustainable textile industry.

Frequently Asked Questions

Which fabrics are best for digital printing?

Fabrics such as cotton, silk, polyester, linen, and rayon work beautifully for digital printing. The choice of ink and process depends on the specific fabric type.

Does digital printing fade over time?

When properly fixed and cared for, digital prints are long-lasting and resistant to fading. Using gentle detergents and avoiding harsh sunlight helps preserve colors.

Is digital printing suitable for custom or small orders?

Yes, digital printing is perfect for small runs and one-off designs. It eliminates setup costs, making it affordable for custom projects.

Is digital printing on fabric eco-friendly?

Absolutely. It uses less water and fewer chemicals than traditional printing methods, and many manufacturers use non-toxic, water-based inks.

Can I use my own design for printing?

Yes, one of the biggest advantages of digital printing is that customers can print their unique designs, photographs, or artwork directly onto fabrics.

Conclusion

Custom digital printing on fabric represents a new era of textile creativity — one where imagination has no boundaries. It brings together technology, sustainability, and design freedom, allowing every piece of fabric to tell a unique story.

From fashion houses and interior designers to small businesses and independent artists, this method empowers creators to transform ideas into reality with remarkable ease and precision.